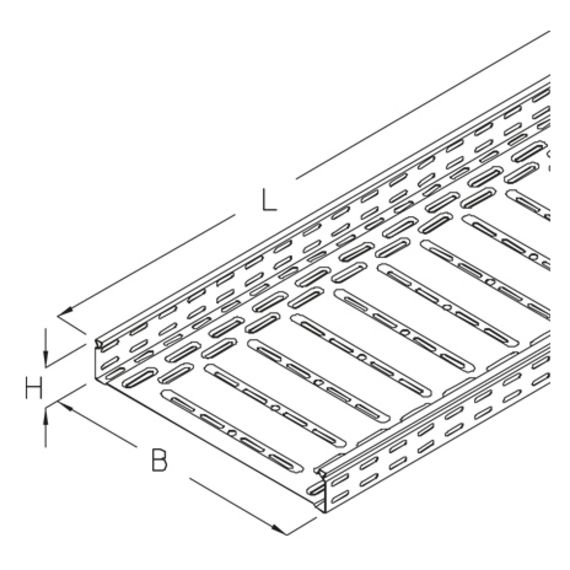

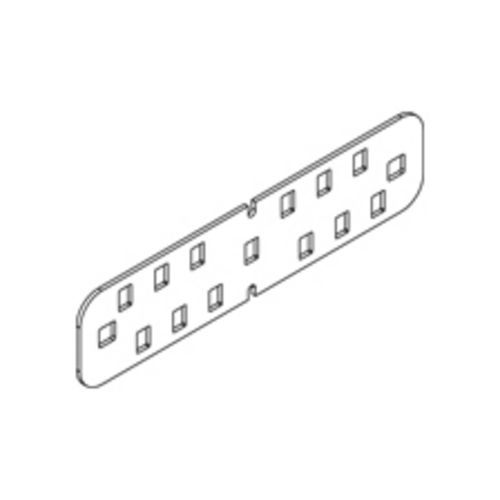

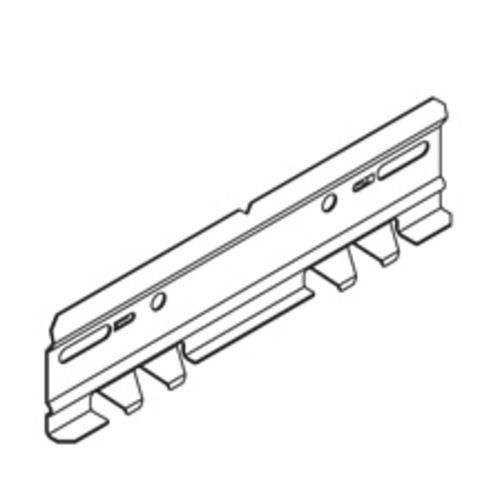

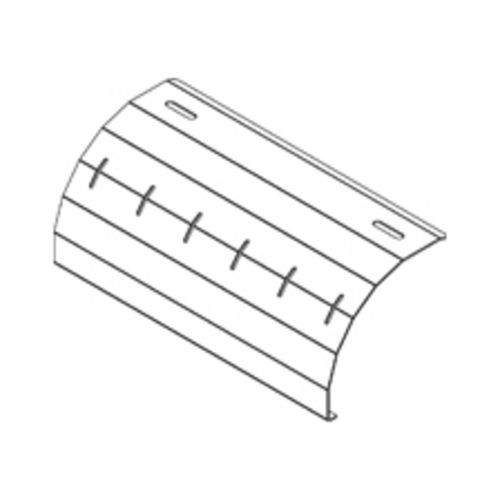

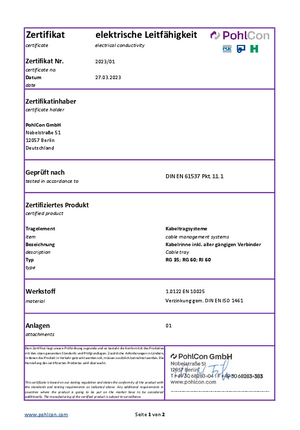

cable tray perforated, head shape suitable for positive locking covers, with longitudinal and lateral reinforcing rims reducing bottom deflection, certified including electrical conductivity according to DIN EN 61537

This article is available made in material No. 1.4571/1.4404 (V4A) stainless steel finish.

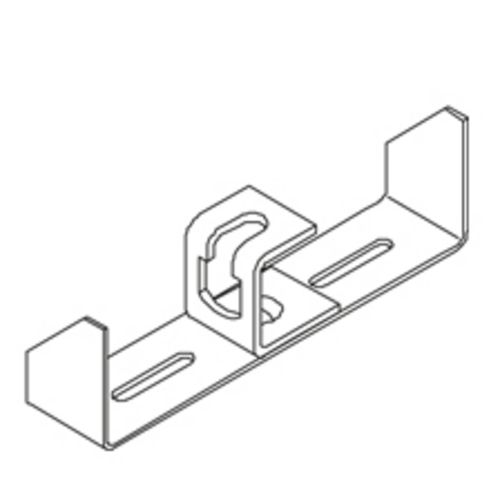

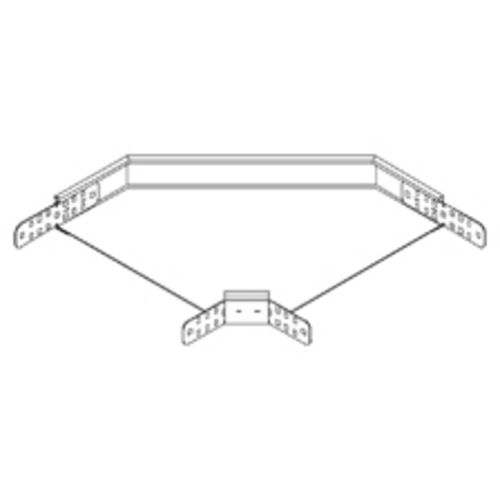

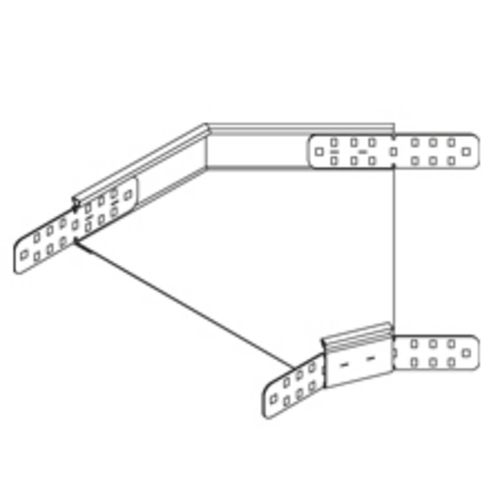

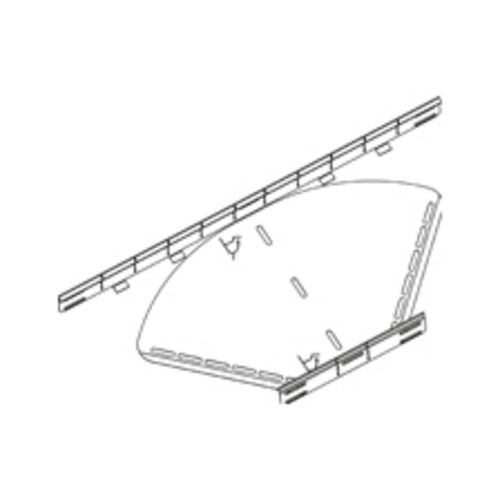

Assembly Instruction Continously hot galvanized (Sendzimir process) (DIN EN 10346)

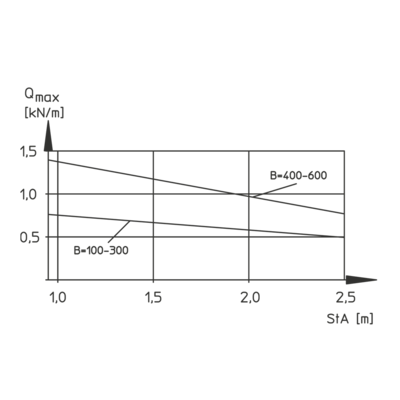

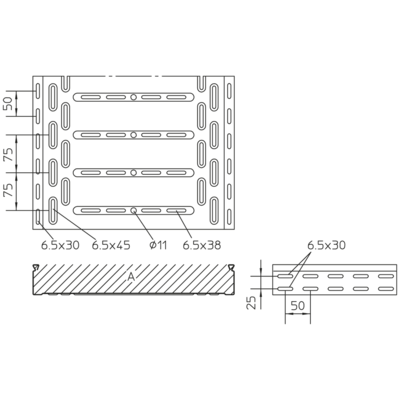

| height | width | length | t material thickness | A cross section area | QSKdistributed load control cable | weight | ||

|---|---|---|---|---|---|---|---|---|

| RG 60-05S | 60 mm | 50 mm | 3000 mm | 0,75 mm | 27 cm² | 0,04 kN/m | 3,40 kg | |

| RG 60-10S | 60 mm | 100 mm | 3000 mm | 0,75 mm | 57 cm² | 0,09 kN/m | 4,30 kg | |

| RG 60-20S | 60 mm | 200 mm | 3000 mm | 0,75 mm | 117 cm² | 0,18 kN/m | 5,80 kg | |

| RG 60-30S | 60 mm | 300 mm | 3000 mm | 0,75 mm | 177 cm² | 0,27 kN/m | 7,40 kg | |

| RG 60-40S | 60 mm | 400 mm | 3000 mm | 0,88 mm | 237 cm² | 0,36 kN/m | 10,60 kg | |

| RG 60-50S | 60 mm | 500 mm | 3000 mm | 1,00 mm | 297 cm² | 0,45 kN/m | 14,20 kg | |

| RG 60-60S | 60 mm | 600 mm | 3000 mm | 1,00 mm | 357 cm² | 0,54 kN/m | 16,40 kg |

Hot-dip galvanized, according to BS 729 (DIN EN ISO 1461)

| height | width | length | t material thickness | A cross section area | QSKdistributed load control cable | weight | ||

|---|---|---|---|---|---|---|---|---|

| RG 60-05F | 60 mm | 50 mm | 3000 mm | 0,75 mm | 27 cm² | 0,04 kN/m | 3,80 kg | |

| RG 60-10F | 60 mm | 100 mm | 3000 mm | 0,75 mm | 57 cm² | 0,09 kN/m | 4,80 kg | |

| RG 60-20F | 60 mm | 200 mm | 3000 mm | 0,75 mm | 117 cm² | 0,18 kN/m | 6,50 kg | |

| RG 60-30F | 60 mm | 300 mm | 3000 mm | 0,75 mm | 177 cm² | 0,27 kN/m | 8,30 kg | |

| RG 60-40F | 60 mm | 400 mm | 3000 mm | 0,88 mm | 237 cm² | 0,36 kN/m | 11,70 kg | |

| RG 60-50F | 60 mm | 500 mm | 3000 mm | 1,00 mm | 297 cm² | 0,45 kN/m | 15,70 kg | |

| RG 60-60F | 60 mm | 600 mm | 3000 mm | 1,00 mm | 357 cm² | 0,54 kN/m | 18,10 kg |

Stainless steel, according to ASTM 304 / BS 304 S 3

| height | width | length | t material thickness | A cross section area | QSKdistributed load control cable | weight | ||

|---|---|---|---|---|---|---|---|---|

| RG 60-05E | 60 mm | 50 mm | 3000 mm | 0,80 mm | 27 cm² | 0,04 kN/m | 3,60 kg | |

| RG 60-10E | 60 mm | 100 mm | 3000 mm | 0,80 mm | 57 cm² | 0,09 kN/m | 4,60 kg | |

| RG 60-20E | 60 mm | 200 mm | 3000 mm | 0,80 mm | 117 cm² | 0,18 kN/m | 6,20 kg | |

| RG 60-30E | 60 mm | 300 mm | 3000 mm | 0,80 mm | 177 cm² | 0,27 kN/m | 8,00 kg | |

| RG 60-40E | 60 mm | 400 mm | 3000 mm | 0,80 mm | 237 cm² | 0,36 kN/m | 9,90 kg | |

| RG 60-50E | 60 mm | 500 mm | 3000 mm | 1,00 mm | 297 cm² | 0,45 kN/m | 14,30 kg | |

| RG 60-60E | 60 mm | 600 mm | 3000 mm | 1,00 mm | 357 cm² | 0,54 kN/m | 16,60 kg |

Brandschutz nach DIN 4102-12

Brandschutz nach DIN 4102-12  Conductividad eléctrica según la norma DIN EN 61537 punto 11.1 (RG 35/60 y RI 60)

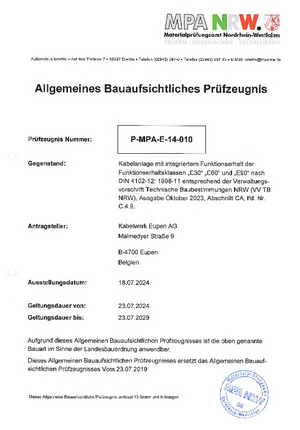

Conductividad eléctrica según la norma DIN EN 61537 punto 11.1 (RG 35/60 y RI 60)  Funktionserhalt - abP - P-MPA-E-14-010 - KDU60

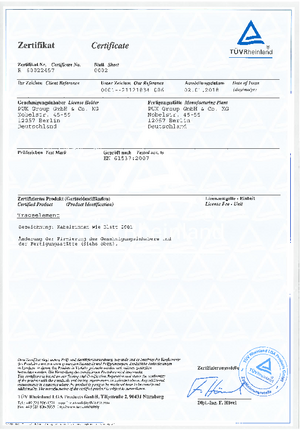

Funktionserhalt - abP - P-MPA-E-14-010 - KDU60  Test certificate for TÜV testing, tested according to EN 61537:2007, RG, RGS, cable trays

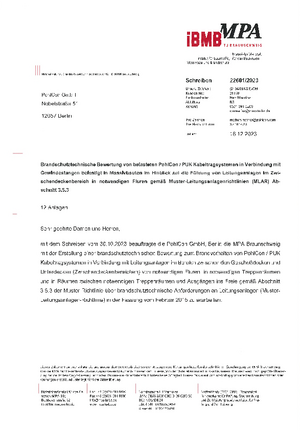

Test certificate for TÜV testing, tested according to EN 61537:2007, RG, RGS, cable trays  Fluchtweginstallation - MLAR

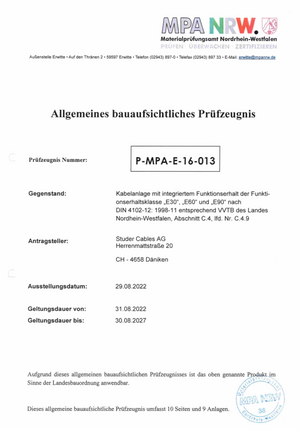

Fluchtweginstallation - MLAR  Funktionserhalt - abP - P-MPA-E-16-013 - KDU57 - KDU60

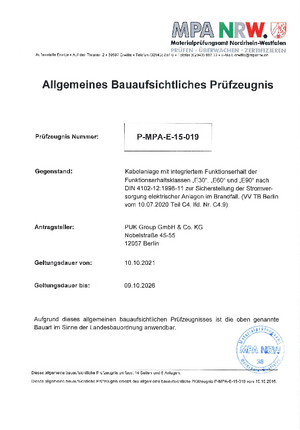

Funktionserhalt - abP - P-MPA-E-16-013 - KDU57 - KDU60  Funktionserhalt - abP - P-MPA-E-15-019 - KDU57

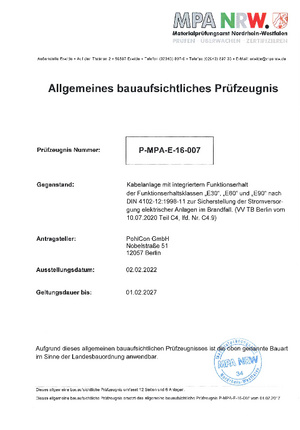

Funktionserhalt - abP - P-MPA-E-15-019 - KDU57  Funktionserhalt - abP - P-MPA-E-16-007 - KDU60

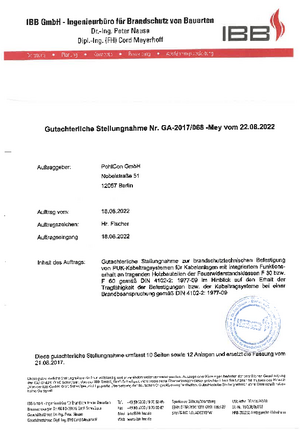

Funktionserhalt - abP - P-MPA-E-16-007 - KDU60  Funktionserhalt an tragenden Holzbauteilen

Funktionserhalt an tragenden Holzbauteilen